Critical Minerals

A decarbonized energy future depends on critical minerals

The demand for minerals for the energy transition—and our modern lives—is set to outpace current available supply. In fact, demand for critical minerals will more than double by 2030, according to IEA, the International Energy Association.

When it comes to the global race to electrification, Stantec can support the responsible extraction and development of copper, nickel, lithium, graphite, and rare earth elements (REEs) around the world. How? We deploy a technology-forward approach to help meet the growing demand for critical mineral raw material supply. We help mining juniors and majors access federal funding, and we help them navigate challenging permit schedules.

Our engineering support can help you reduce risks and move mining projects through feasibility to detailed engineering and construction. If you’re looking for scaling solutions, we support transitions from pilot studies to full production.

Critical mineral production is a global challenge—let us help you meet these crucial industry needs.

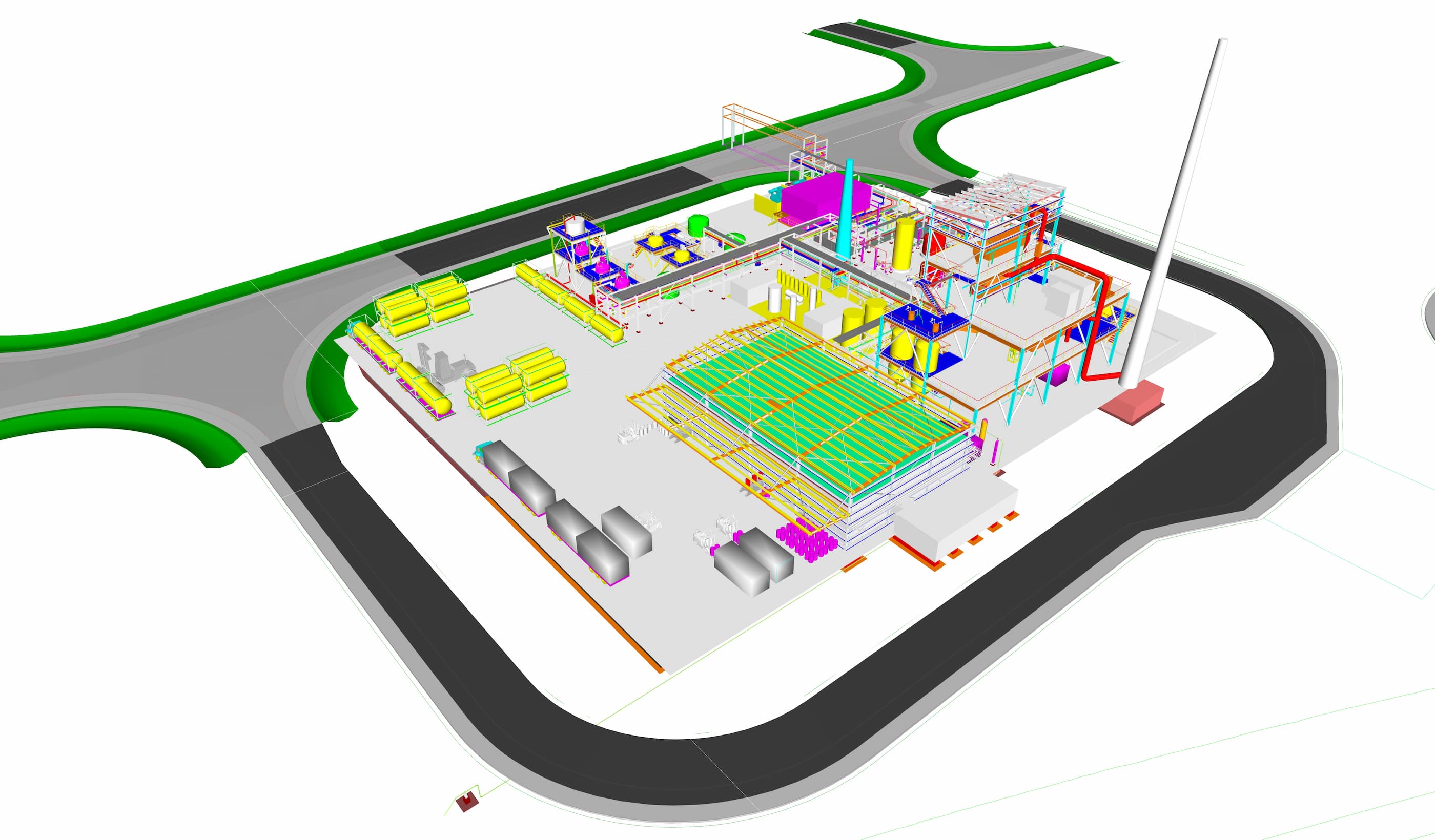

Scaling up your critical minerals processing with demonstration plants

When you need to scale technology solutions from pilot studies to full production, we can help—and we can help in timeframes that support speed to market. Let’s partner to create strategies that generate profitability throughout the mining project operation and balance starting capital expenses. Strategies such as efficiency audits or considering alternative power solutions to attract environmental, social, and governance (ESG) investment dollars. Read MoreEnvironmental approvals and permitting for mine sites

To grow the critical minerals market, we need to increase new mine site exploration and expand existing mines. To help you reduce the environmental impacts of mining, our team provides environmental assessment, permitting, and approval support services. Supporting projects of all sizes and complexity, our strong understanding of federal, state, and local regulatory agencies will simplify your permitting process. Let’s work together to responsibly extract critical minerals while complying with environmental guidance. Read MoreMining critical minerals for the energy transition

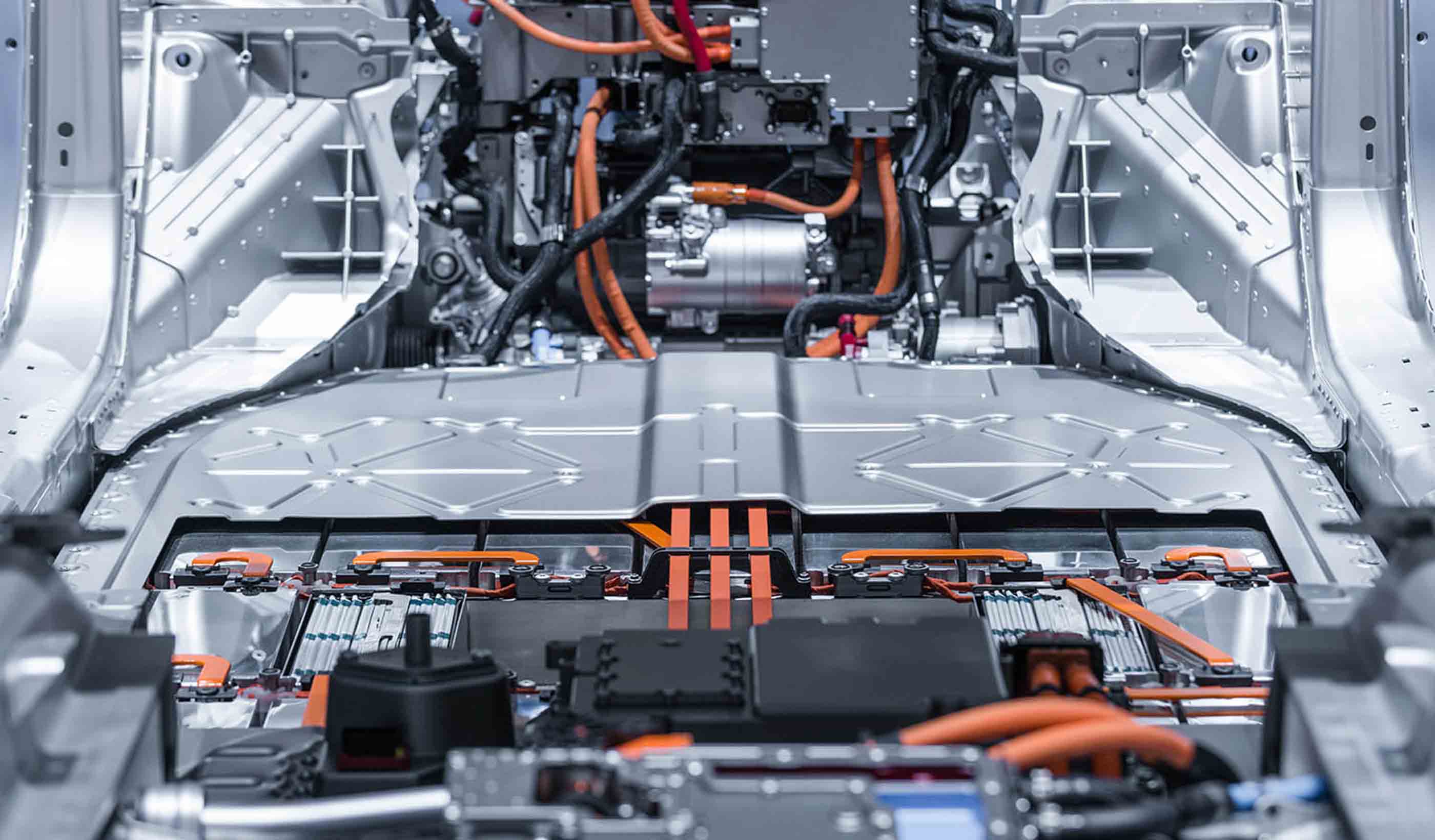

The energy transition is driving demand for critical minerals and metals around the world. From lithium and nickel to graphite and rare earth elements, these resources are needed to produce the renewable energy technologies of the future. Our teams are positioned to support mining projects through the entire lifecycle. From exploration and permitting through to mine closure and asset transformation, our integrated mining teams can support you from before a project starts until long after it’s finished. Read MoreCritical minerals processing

Every day, we’re seeing more electric vehicles and solar panels—and that also means a rapidly increasing demand for critical minerals processing. We have projects and operations experience recovering gold, copper, platinum group metals, and rare earth elements, and our specialists can also provide guidance in lithium, nickel, cobalt, and vanadium extraction. If you’re developing an extraction project or managing a mining site, we can help you reliably and responsibly access your mineral resources—getting from rock to ore. Read MoreOur People

-

Kevin Kammerzell

Vice President, Mine Site Infrastructure

-

Cody Ryckman

Innovation & Technology Lead, Mining, Minerals, and Metals

-

Henlo Du Preez

Regional Practice Technology Leader, Industrial Water

-

Rosario Urrutia

Country Manager, Chile

-

Mark Wilson

Vice President, Renewables, Heavy Industrial Process, and Thermal Sector Leader

-

Mike Voll

Principal, Sector Lead Smart Technologies

-

Scott Trusler

Vice President, Mining Sector Lead, Environmental Services

-

Jason Doupe

Vice President, Environmental Services

-

David Thatcher

Vice President, Transportation

-

Ken Martins

Global Practice Leader, Industrial Water

-

Dena Abakumov

Principal, Transit & Rail Sector Lead

-

Russell Saputo

Vice President, Roadways Sector Leader (US)

-

Luis Arcos

Mining Manager

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.