Critical Minerals

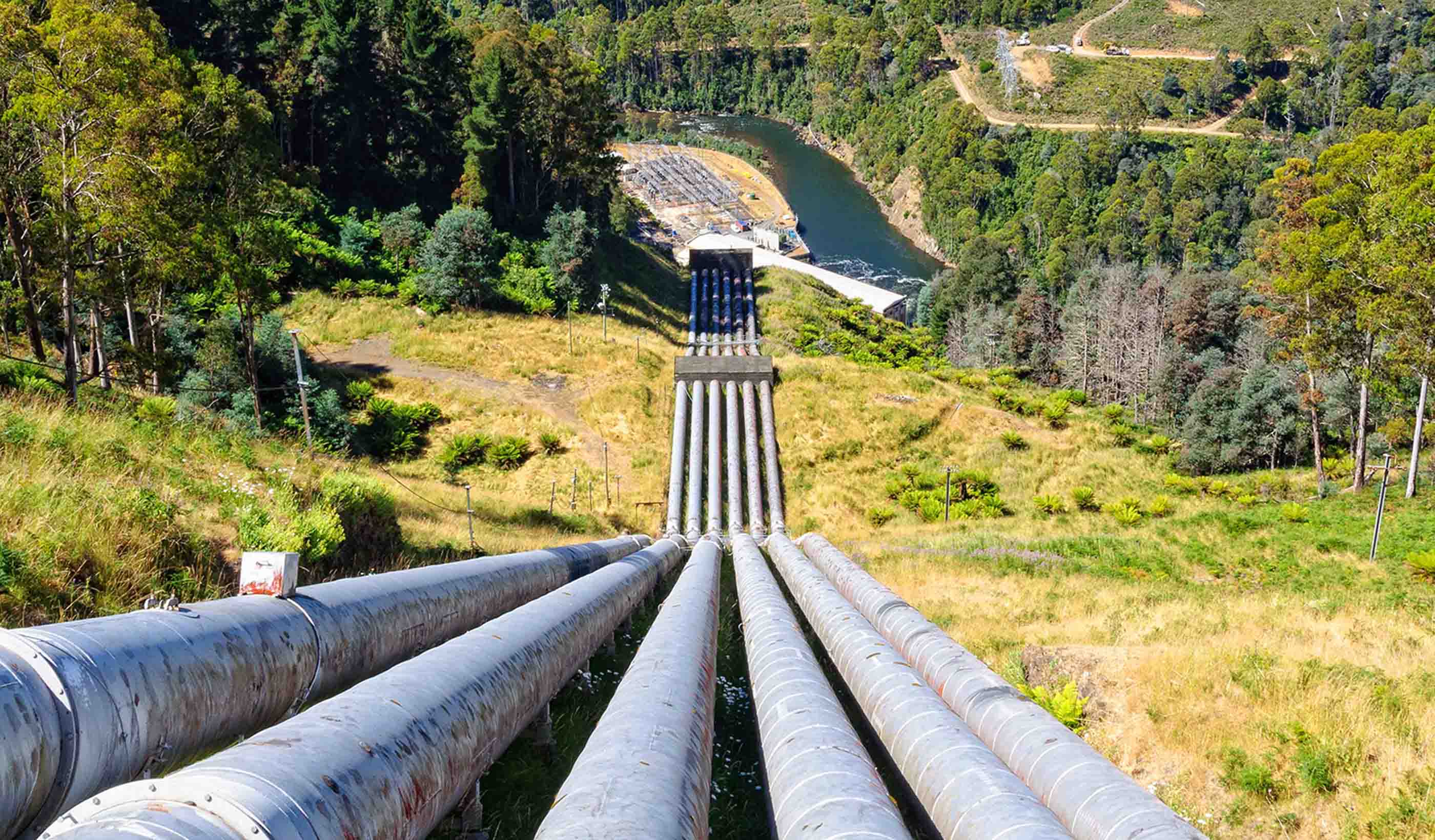

Readying the world's critical minerals

The demand for base and critical minerals for the energy transition—and our modern lives—is set to outpace currently available supply.

In Australia, we need to find ways to scale-up critical minerals processing so we can meet increasing demand as a global supplier. According to Geoscience Australia, in 2022, Australia was the world’s number one lithium producer (52%).

Stantec can support the responsible extraction and development of all types of critical minerals including copper, lithium, high purity alumina, nickel, vanadium, and rare earth elements (REEs).

We move mining projects through the piloting, and commercial study phases to detailed engineering, design, and construction. If you’re looking to scale your production to meet demand, we can support your transition from the laboratory to a demonstration plant to a commercial-scale processing plant.

Readying the world's critical minerals is a global challenge—let us assist you to meet these market needs.

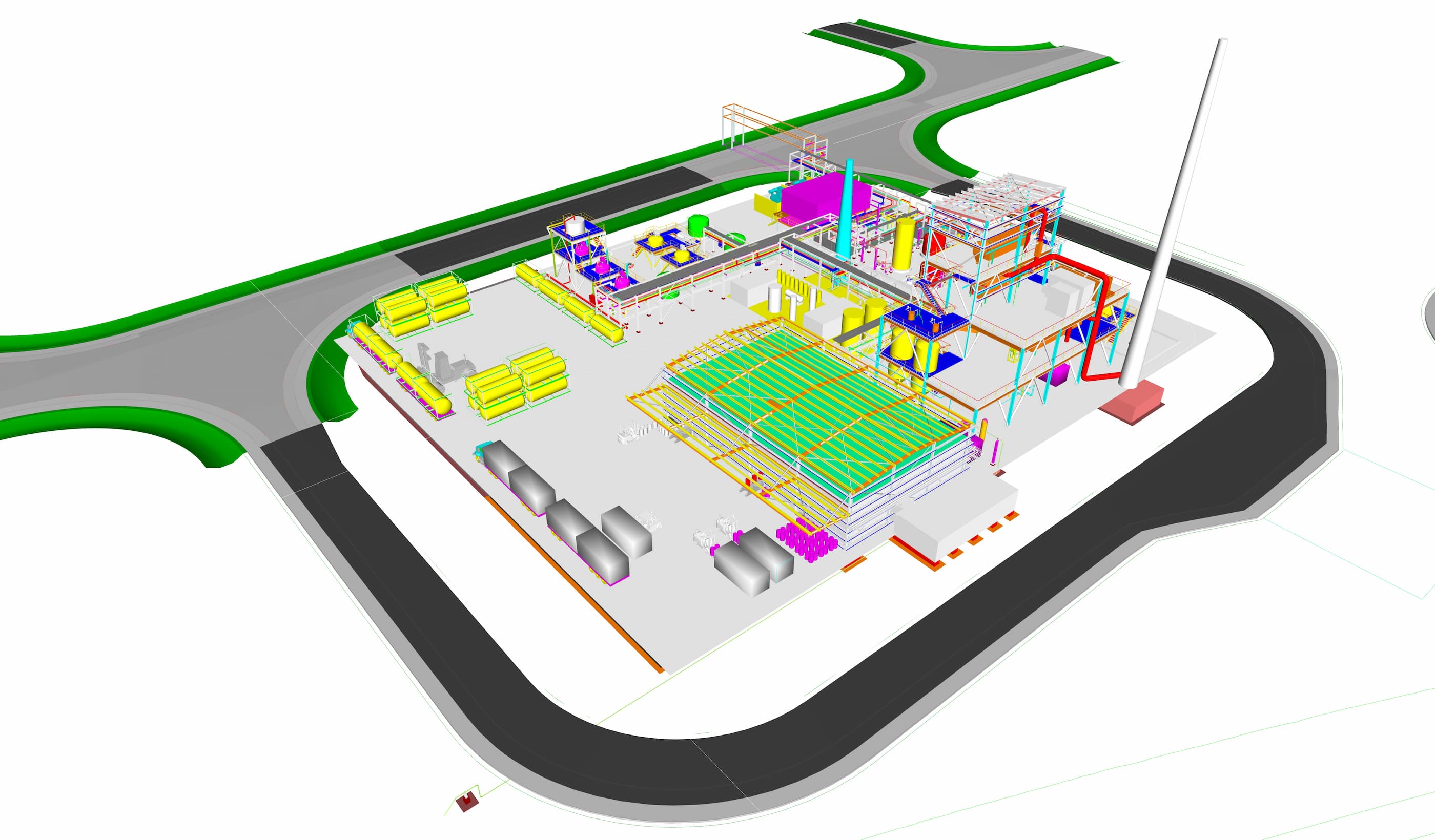

Demonstration plants for scaling production to meet demand

Extracting and processing critical minerals and rare earth elements often involves a high degree of technical difficulty. Demonstration plants play a key role in allowing mining companies to test critical minerals processing at scale before investing in a commercial processing plant. We’re designing and building demonstration plants, helping our clients validate new technologies, materials of construction, mitigate risks, assess their performance, and investigate economic viability before they build a plant at commercial scale. Read MoreSustainable critical minerals processing

Rapidly increasing demands for critical minerals drives the need for sustainable mineral processing methods. We have project and operations experience recovering all critical minerals and metals including copper, rare earth elements, lithium, nickel, cobalt, high purity alumina, and vanadium. If you’re developing an extraction project or managing a mining site, we can help you reliably and responsibly access your resources from rock to ore and pit to port. Read MoreRevalorisation of critical minerals in tailings waste

Finding ways to reduce or reuse mine tailings can have significant environmental, safety, and economic advantages. Utilising the latest technologies and processing methods, our process engineers can help you identify, value, and extract critical minerals and other commodities from tailings waste that previously would have been unused. Transforming tailings into a valuable resource further supports the increased demand for metals and minerals and a more sustainable mining industry. Read MoreEnvironmental approvals for mine sites

With Australia’s aim to grow the critical minerals sector, we need to increase new mine site exploration and expand our existing mines. To help you reduce the environmental impacts of mining, our team provides environmental assessment, permitting, and approval services. Supporting projects of all sizes and complexity, our strong connections with regulatory authorities will simplify your permitting needs, leading to a more efficient approval process. Let us assist you in the environmentally conscious extraction of critical minerals. Read MoreOur People

-

Carl Kopke

Regional Director, Energy & Resources (Australia)

-

Damian Pianta

Project Manager

-

Peter Tapsell

Senior Principal Environmental Scientist / Team Lead, Mining Approvals

-

Mark Richter

Client Development & Portfolio Manager

-

Bikram Singh

Business Leader, Energy & Resources WA

-

Walter Weinig

Discipline Leader, Hydrogeology and Mine Closure Specialist

-

Daniel Martinez

Senior Project Manager

-

Tavis Mackenzie

Principal Project Manager

-

Dr. Fiona Taukulis

Business Leader, Environment, Western Australia

-

Ratheesh Kuppusamy

Senior Principal, Structural Engineer

-

Andy Williams

Business Leader, Geosciences, QLD

-

Jeremy Tape

Discipline Leader, Process

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.