At a Glance

-

2.5

Kilometers long sea outfall

-

95M

Liters of treated wastewater

-

£300M

Improvement scheme

- Location

- Sussex, United Kingdom

- Offices

-

-

Client

-

-

Southern Water

-

-

Awards

-

Project of the Year at the 2014 Construction News Awards

-

-

Major Civil Engineering Project of the Year (Over £50m) - British Construction Industry Awards 2013

-

-

ICE Brassey Award for the best civil engineering plant in Kent and East Sussex 2013

- Location

- Sussex, United Kingdom

- Offices

- Client

-

- Southern Water

- Awards

- Project of the Year at the 2014 Construction News Awards

- Major Civil Engineering Project of the Year (Over £50m) - British Construction Industry Awards 2013

- ICE Brassey Award for the best civil engineering plant in Kent and East Sussex 2013

Share

Brighton & Hove WwTW Scheme

Stantec worked collaboratively with Southern Water to deliver major environmental improvements at Brighton and Hove Wastewater Treatment Works in Peacehaven, East Sussex, UK. The Works treats the 95 million litres of wastewater generated each day to required European standards. The treated effluent is returned to the environment 2.5 kilometres off-shore.

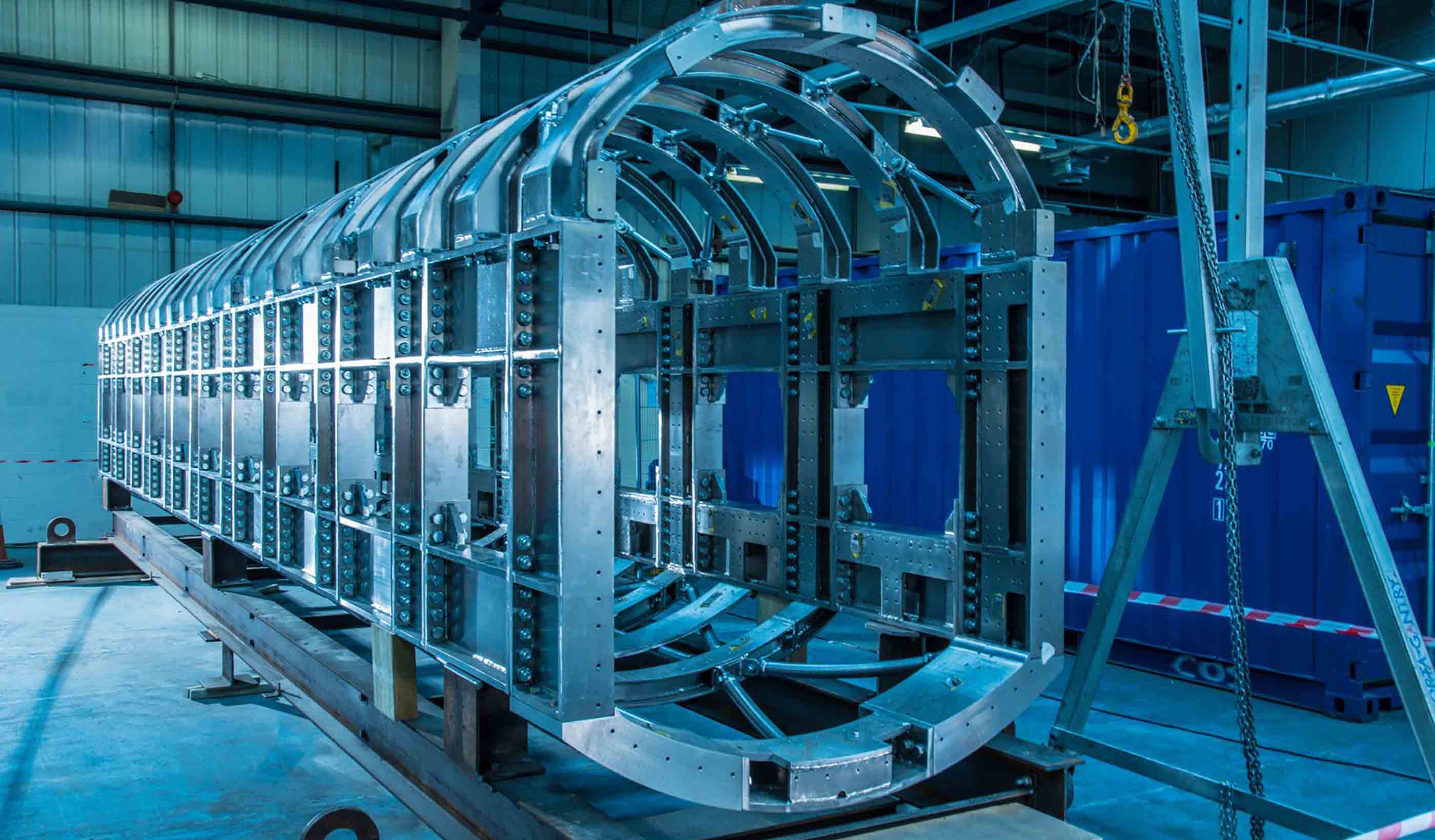

Stantec designed the wastewater treatment works, Marine Drive pumping station, and Portobello pumping station. We were also responsible for the detailed design of the civil, architectural, and reinforced concrete works, the pumping station superstructures on the sewerage system, and the local sewer connections.

Environmental impact was a key focus in the planning approval process. Additionally, odour, noise, and visual impact were three main considerations. Stantec ensured that it took all environmental requirements into account when carrying out the detail design, working in collaboration with multiple designers and contractors who carried out assessments in the planning phase of the scheme.

The wastewater treatment includes a high-rate primary sedimentation process, a high-rate biological treatment process, screens and screenings processing, and grit and grease removal and processing. Indigenous sludge, plus imported sludges from other sites is anaerobically digested on site prior to dewatering. The biogas produced by the digestion plant is used in a CHP plant to produce electricity. An extensive odour control system extracts and treats odours linked to the treatment processes on site. The three-stage process, consisting of an acid and alkali treatment plus carbon polishing, is applied before the cleaned air is released through a chimney-like structure.

We designed this state-of-the-art wastewater treatment works to be sunk into the landscape to minimise its visual impact and covered by one of the largest green roofs in Europe so that it blends in with the surrounding landscape.

At a Glance

-

2.5

Kilometers long sea outfall

-

95M

Liters of treated wastewater

-

£300M

Improvement scheme

- Location

- Sussex, United Kingdom

- Offices

-

-

Client

-

-

Southern Water

-

-

Awards

-

Project of the Year at the 2014 Construction News Awards

-

-

Major Civil Engineering Project of the Year (Over £50m) - British Construction Industry Awards 2013

-

-

ICE Brassey Award for the best civil engineering plant in Kent and East Sussex 2013

- Location

- Sussex, United Kingdom

- Offices

- Client

-

- Southern Water

- Awards

- Project of the Year at the 2014 Construction News Awards

- Major Civil Engineering Project of the Year (Over £50m) - British Construction Industry Awards 2013

- ICE Brassey Award for the best civil engineering plant in Kent and East Sussex 2013

Share

Cath Schefer, Executive Vice President & Chief Operating Officer – Global

I’m passionate about bringing the combined knowledge and expertise of Stantec’s people across the world to deliver great projects for our clients and communities.

Liz Chapman, Director of Technical Design Services

Innovation isn’t just about thinking up new ideas; it can also be about bringing ideas from elsewhere and adopting them.

Scott Jackson, Regional Director, Water

I have an open and honest leadership style which helps my team deliver innovative project solutions for our clients and communities.

John Ord, Business Director, Energy & Resources

The UK energy business is changing rapidly. We assist our clients across the industry to shape and improve transitional and future energy projects.

Craig McMaster, Head of Programme Management and Integrator Services

Supporting our clients create high performing enterprise structures for the efficient delivery of major capital investments is the foundation of my role at Stantec.

Timothy Williams, Strategic Growth & Business Development Director, Water

Communication at all levels, within and between organisations, is paramount to business success.

Jamie Woods, Regional Director, Water Cycle

Collaboration has always been at the heart of my approach – not just in technical delivery, but also business leadership.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.