At a Glance

-

120K

Barrels Per Day

- Location

- Bonnyville, Alberta

- Offices

-

- Location

- Bonnyville, Alberta

- Offices

Share

CNRL Wolf Lake Thermal In Situ

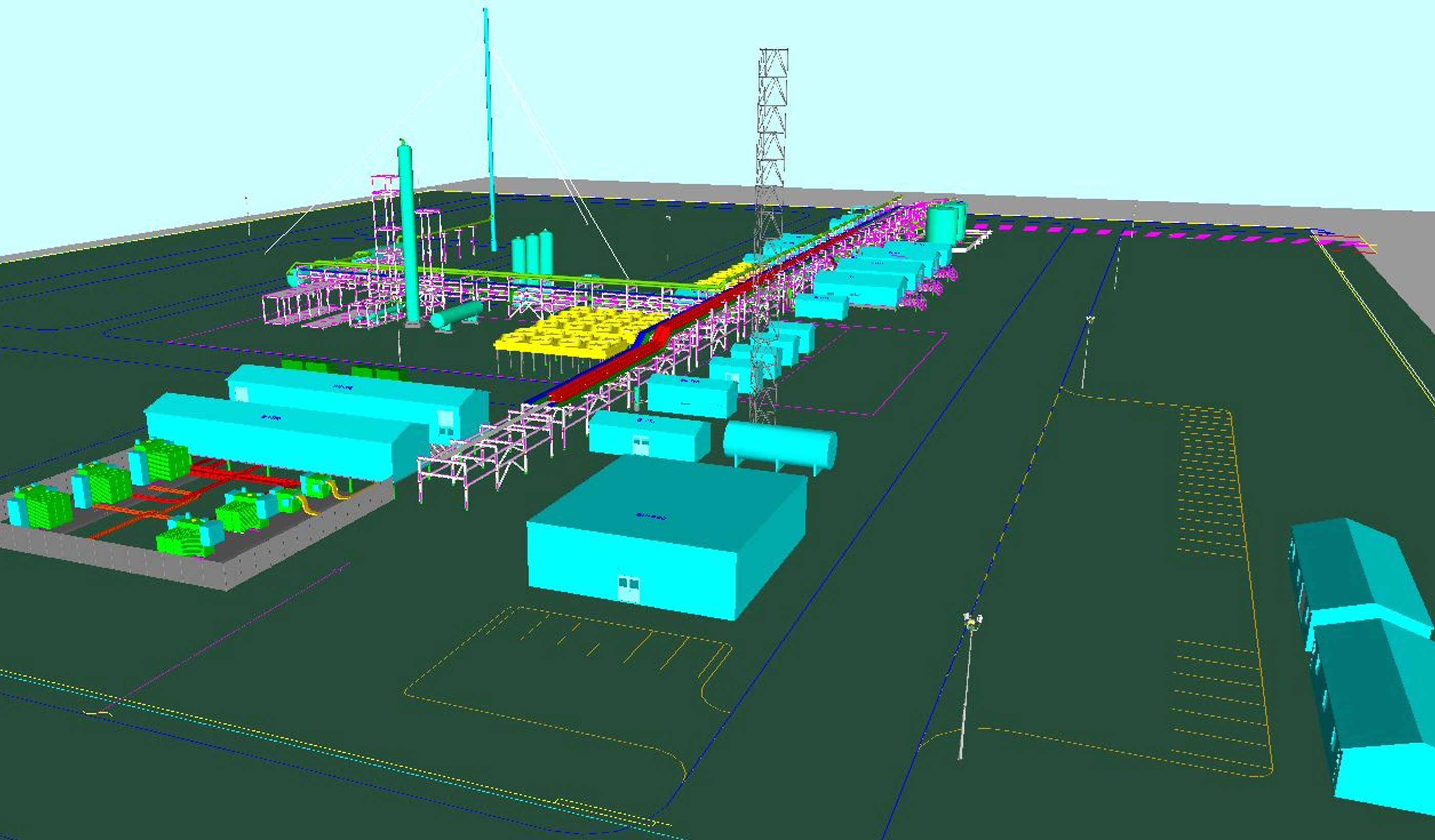

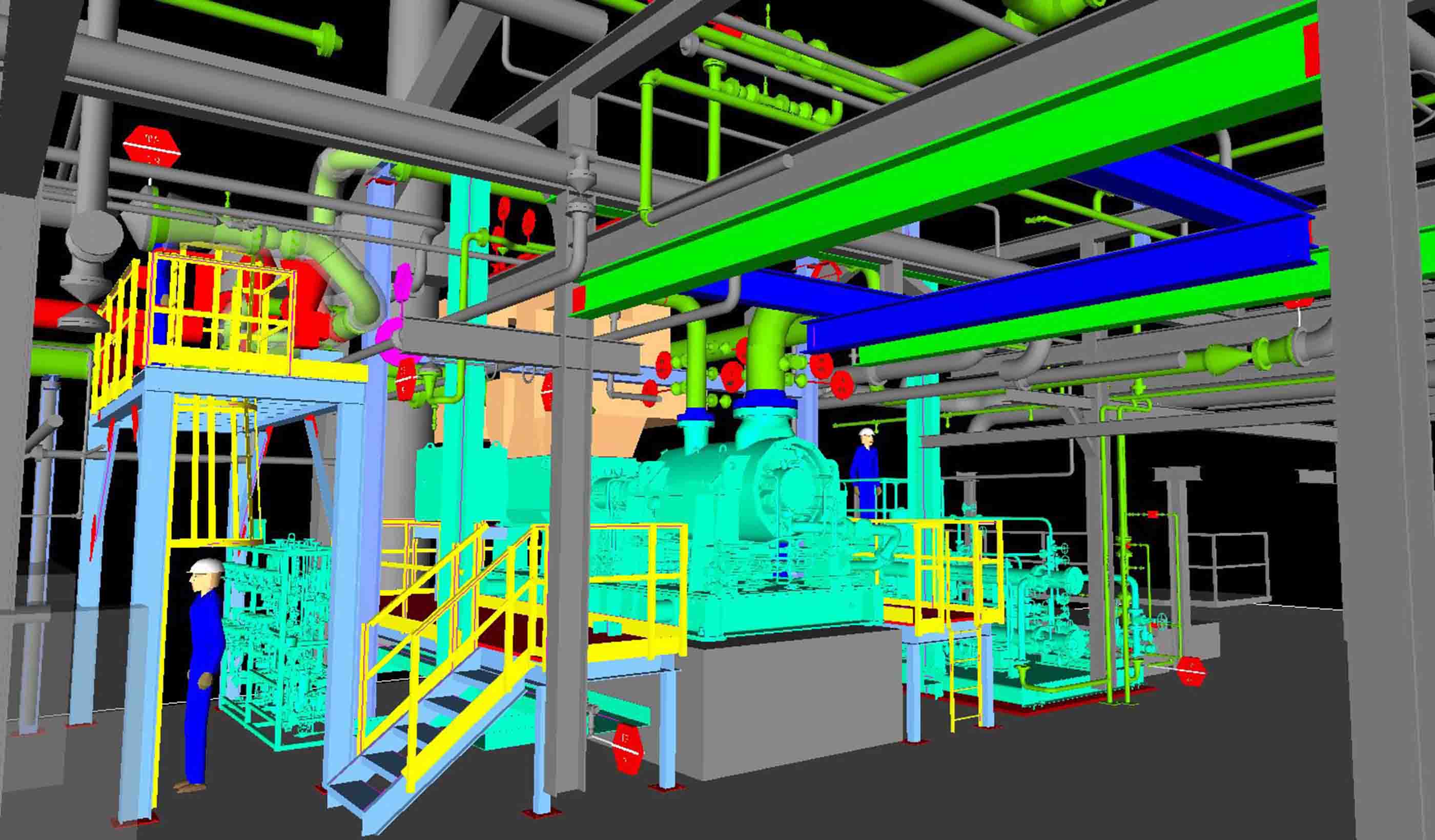

Working together isn’t a concept that’s exclusive to people. At CNRL’s Wolf Lake operation, multiple pieces of equipment must work together as smoothly as soft butter on toast to fuel the slop oil treatment process.

By installing a centrifuge system and associated equipment, CNRL can treat and recover slop oil at the plant and keep operations at Wolf Lake clean and lean. This new system means equipment lasts longer, there’s less cleaning and desanding, chemical costs are lower, and performance is more reliable.

To get to these great results, everything from the building’s concrete foundation up had to work as one. From new oil tanks, pumps, and a centrifuge package, to slurry injection tanks and pumps, we made sure everything performed as planned.

Our engineering and design team worked on multiple engineering packages to the satisfaction of CNRL. We took care of everything from piping and instrumentation diagrams to procuring equipment. We also handled mechanical and instrument datasheets, motor control and power design, pile and concrete foundation design, SD Key and control philosophy and schematics, stress analysis, and modelling.

At a Glance

-

120K

Barrels Per Day

- Location

- Bonnyville, Alberta

- Offices

-

- Location

- Bonnyville, Alberta

- Offices

Share

Jeremy Randle, Senior Associate

In the automation disciplines, we make things work safely and reliably for our clients. I love making things work!

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.