At a Glance

-

$760M

Construction Value

-

55

Acre Site

-

750

Jobs To Be Created

- Location

- Weirton, West Virginia

- Offices

-

- Location

- Weirton, West Virginia

- Offices

Share

Form Factory 1 Iron-Air Battery Production Facility

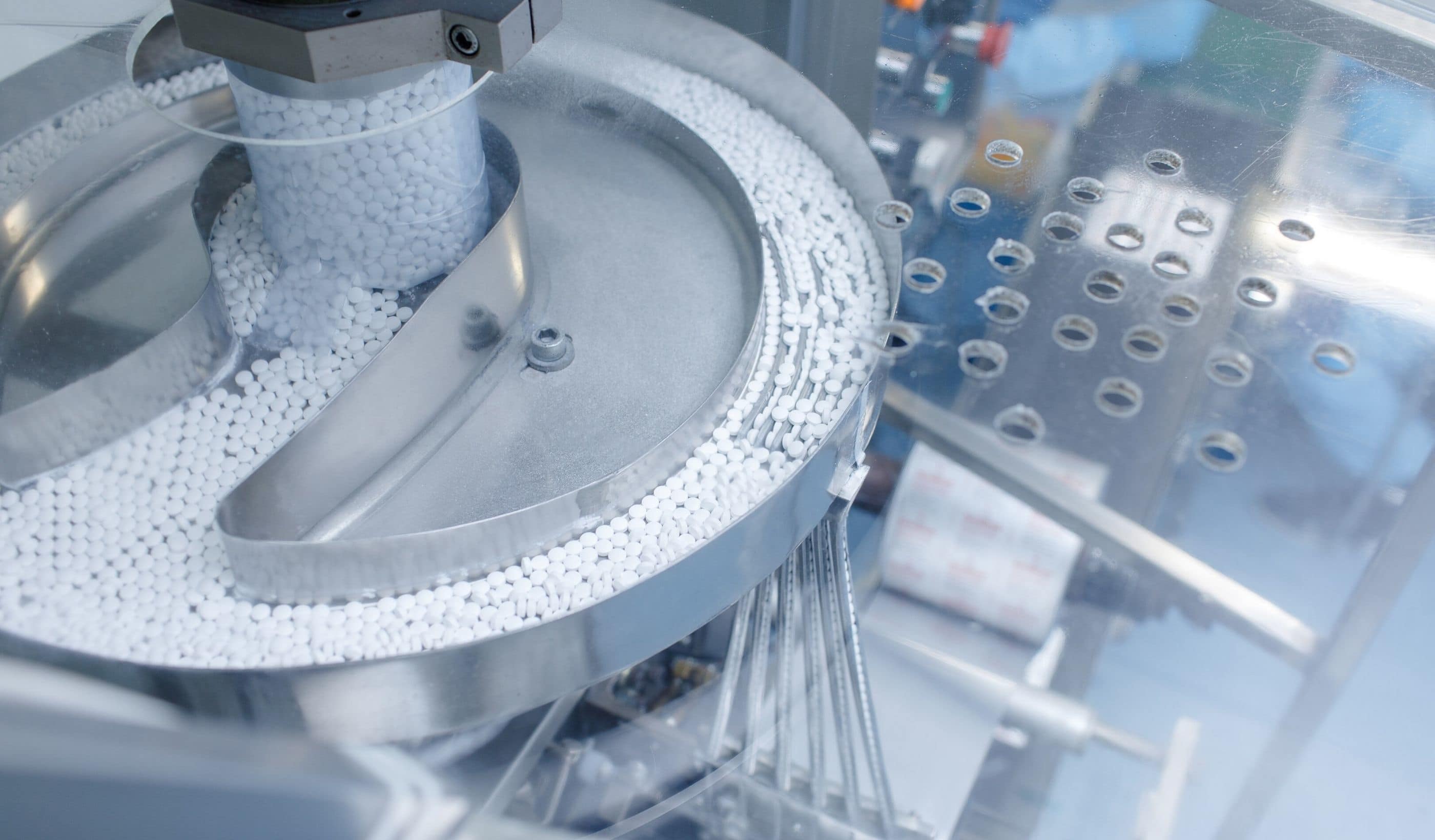

Form Energy’s first commercial product is a rechargeable iron-air battery capable of continuously discharging electricity for 100 hours.

The active components of the iron-air battery system are some of the safest, cheapest, and most abundant materials on the planet—low-cost iron, water, and air. When discharging, an iron-air battery breathes in oxygen and converts iron to rust. While charging, an electrical current converts the rust back to iron and the battery breathes out oxygen.

Time to market is critical for battery production plants amid the increase in renewable energy generation and associated demand for energy storage solutions. That’s why Form Energy had to fast-track their new manufacturing facility set to produce 100-hour iron-air batteries.

Our job? To provide architecture, buildings engineering, and industrial engineering services on Form Factory 1—a project which also brought new purpose to the former Weirton Steel Mill site in West Virginia.

Form Factory 1 is expected to begin operation in mid-to-late 2024. When fully operational, the facility will have an annual production capacity of 500 megawatts of batteries and support technologies capable of cost-effectively storing electricity for multiple days—during extended periods of extreme weather, grid outages, or low renewable generation.

At a Glance

-

$760M

Construction Value

-

55

Acre Site

-

750

Jobs To Be Created

- Location

- Weirton, West Virginia

- Offices

-

- Location

- Weirton, West Virginia

- Offices

Share

Jim Radock, Principal

I consider myself fortunate to work at a firm that fosters such a collaborative environment to serve the needs of a wide array of clients.

Dave Calder, Vice President, Regional Growth Leader, Buildings (Global)

My job is to listen to my clients and figure out what their needs are to see if, and how, Stantec can help them.

Alan Schnerch, Principal, Industrial Engineering Practice Lead

I work with our clients to ensure that process optimization and building design go hand-in-hand—as they should.

Kate Csontos, Principal

Reducing unnecessary static creates a platform where we focus on a common goal and efficiently achieve world and life changing results.

Jeremiah Brooks, Principal

I believe design is processing complex problems and offering simple solutions.

We’re better together

-

Become a client

Partner with us today to change how tomorrow looks. You’re exactly what’s needed to help us make it happen in your community.

-

Design your career

Work with passionate people who are experts in their field. Our teams love what they do and are driven by how their work makes an impact on the communities they serve.