Fueling the future: The promise of hydrogen fuel

October 02, 2024

October 02, 2024

Hydrogen fuel can help us to decarbonize our transportation industry in meaningful ways. Here’s how.

The energy transition is driving decarbonization efforts across all industries. This includes the transportation industry. It accounts for more than 25 percent of all greenhouse gas (GHG) emissions. This has led us to rethink our use of the fossil fuel combustion engine.

Now, we’re seeking out more sustainable modes of transportation. Most people are likely familiar with electric vehicles (EVs). But what about another form of low-carbon transportation? Hydrogen fuel-cell vehicles.

Hydrogen fuel-cell vehicles are gaining momentum. Policies and initiatives from organizations like the Fuel Cell and Hydrogen Energy Association, Advanced Clean Transportation, and the Hydrogen Council have driven this trend. The vehicles offer great opportunities to cut GHG emissions. This will be especially true as environmental regulations tighten. Even more so as public enthusiasm for cleaner transportation grows. But they also present challenges.

Transitioning from fossil fuels to hydrogen is promising. These vehicles can help us meet our zero-emission targets. Let’s dive into the essentials of hydrogen vehicles, hydrogen fueling stations, and driving a hydrogen economy.

Our teams are providing hydrogen fueling design services for the City of Pasadena Hydrogen Fueling Facility in Pasadena, California.

Hydrogen is a colorless, odorless, and flammable gas. Its diverse production options and potential for near-zero GHG emissions make it an excellent choice for low-carbon fueling. What’s the byproduct when a fuel cell uses hydrogen to generate electricity? Water vapor. That’s it.

How does it work? Fuel cells convert hydrogen gas into electricity. That electricity is then used to power vehicles.

Hydrogen fuel is more efficient than gasoline. This is because of its high energy content and the efficiency of the vehicle fuel cell. Fuel cells convert about 60 percent of hydrogen fuel into usable electrical energy. Gas has a maximum efficiency of about 35 percent. Simply put, we need less hydrogen to fuel a vehicle than gasoline.

Most hydrogen is produced through steam methane reforming (SMR). SMR traditionally releases carbon dioxide (CO₂) and carbon monoxide (CO) into the atmosphere. But there are ways to significantly reduce the carbon intensity of this process. The first is capturing and sequestering the CO₂. The second is using renewable natural gas (RNG) as the feedstock for SMR. Although RNG still produces carbon, it prevents methane from entering the atmosphere. This is crucial as methane has a much greater impact on global warming than CO₂.

We can use water electrolysis to produce hydrogen. This method involves electrical current breaking down purified water into hydrogen and oxygen. It is becoming more popular because it can use renewable energy sources. This is known as green hydrogen, and it emits no GHGs in the process.

Hydrogen molecule.

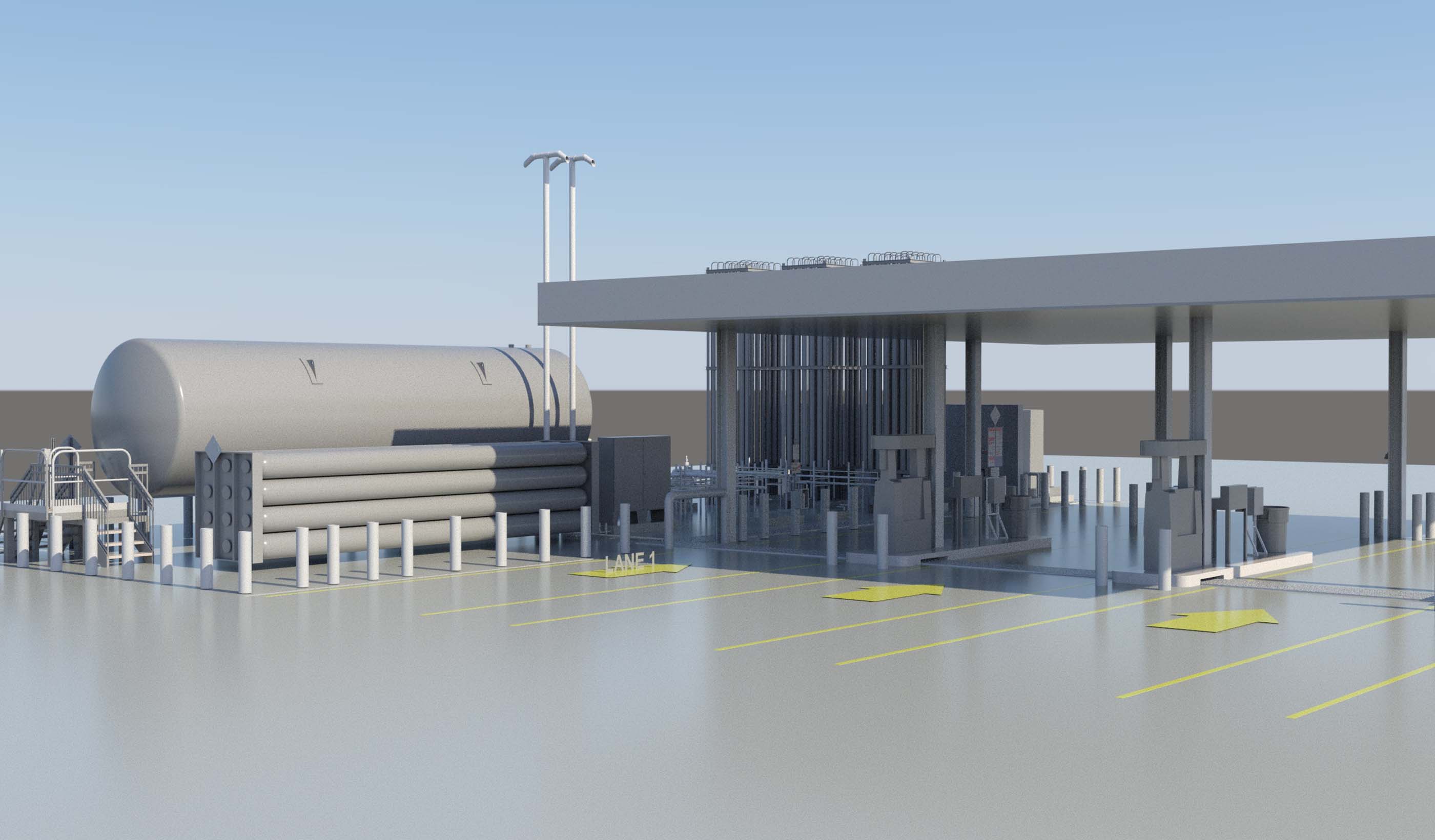

Hydrogen fuel stations look like standard gas stations. But they use specialized equipment and safety measures. There are two main strategies for procuring hydrogen: onsite and offsite production. Each has advantages and disadvantages in terms of environmental impact, space requirements, and cost. So, facility owners must carefully look at their options. Let’s review the pros and cons of the procurement methods of hydrogen.

One method of onsite production is SMR. SMR is a process where high-pressure steam is applied to methane to produce hydrogen, along with CO₂ and CO as byproducts. This is known as blue hydrogen when carbon is captured and grey hydrogen when it is not. It has many advantages. It is more energy efficient. It has a smaller footprint. And it can use existing natural gas infrastructure, including RNG. But there are also drawbacks. These include GHG emissions, a nonadjustable production rate, and significant space requirements. The gas must also be compressed for use in vehicles, and impurities within the fuel are harder to manage.

Water electrolysis is another onsite production method. As we noted above, water electrolysis can produce green hydrogen when paired with renewables. The most obvious benefit here is that the use of renewable energy leads to clean, environmentally friendly production. But this method also offers a more flexible capacity. Plus, we can use the oxygen produced for other things. Some of the negatives include higher costs due to a greater energy input, a larger footprint, and a substantial water input. The process also generates a wastewater stream that must be managed and requires compression for the gas to be used in vehicles.

SunLine Transit is using electrolysis to produce hydrogen onsite. The system includes

Our teams are working with SunLine to improve and optimize the function of the onsite production system. We’re also determining how to best integrate it with SunLine’s fuel-cell electric bus (FCEB) fleet. Options for fueling include stand-alone dispensing, as well as integrating the electrolysis output with SunLine’s new liquid hydrogen-based fueling system.

Hydrogen fuel will play a significant role in transitioning to a low-carbon economy. This is especially true for sectors that are hard to electrify.

Another form of onsite production is autothermal reforming (ATR). ATR converts purified natural gas into hydrogen fuel. As opposed to SMR, ATR adds oxygen, which allows some of the partially reformed gas to combust. This raises the process gas temperature rather than using natural gas. It enables ATR to provide a higher CO₂ capture at a lower cost than SMR. Some benefits of ATR include a faster startup and shutdown time, compact system design, and a simplified carbon capture process. It also allows for greater flexibility with feedstock and potential energy efficiency. Disadvantages of ATR include higher production costs (due to the need for oxygen), a lower hydrogen yield, and catalyst challenges.

Now we move on to offsite production. Trucked-in liquid hydrogen—produced offsite—is a common delivery method. Cryogenic liquid hydrogen is delivered via tanker and stored safely onsite for use. Transporting hydrogen to a site can offer several benefits. Some of these include quick refueling times, less maintenance, and fewer concerns about fuel purity. It also supports large daily fuel consumption, lower electrical requirements, and efficient storage space. Some of the challenges with offsite production? Procurement, low supply, higher costs, and boil-off losses that must be managed.

Right now, our teams are providing engineering design for C-TRAN’s hydrogen fueling facility in Vancouver, Washington. Our hydrogen fueling design team is designing a liquid hydrogen tank and cryogenic pumps that can store hydrogen from offsite and service FCEBs. The design includes locally produced gaseous hydrogen that is connected to the system and augments the liquid supply. When the new facility is complete, C-TRAN will be well on the road to decarbonizing its transit system. This will help to improve air quality through reduced emissions.

Our teams are providing hydrogen fueling design services for the C-TRAN Hydrogen Fueling Facility in Vancouver, Washington.

When the Regional Transportation Commission (RTC) of Southern Nevada decided to transition to hydrogen, our teams were ready to help. We developed a new facility to decarbonize their fleet and support 50 FCEBs. We conducted a feasibility study. It showed that trucked-in liquid hydrogen was the most cost-effective and space-efficient solution. We also designed a temporary hydrogen fueling system. It supports the initial FCEBs with minimal infrastructure requirements. But there was uncertainty about whether the RTC’s FCEB fleet would surpass the 50-bus capacity of the permanent facility. So, we developed a master plan for the fueling facility that allows for future expansion. By embracing FCEBs and the associated infrastructure, the RTC is making a positive community impact.

Our teams are also working with facility owners to design retail hydrogen fueling stations for public use. We are providing design services to establish a network of 10-plus retail hydrogen fueling facilities throughout California. The technical approach? Delivering gaseous hydrogen to the sites via large tube trailers. The gas is then transferred into fixed-storage vessels using station compressors, which are used to compress hydrogen for dispensing at 700 bar. This method avoids the boil-off losses typical of liquid hydrogen systems. It can also work in compact sites.

A hydrogen fuel-cell vehicle refueling at a hydrogen station.

Hydrogen fuel will play a significant role in transitioning to a low-carbon economy. This is especially true for sectors that are hard to electrify. Think heavy-duty trucks, buses, trains, and ships. Hydrogen fuel sources and methods are always evolving. For example, using biogas to produce hydrogen. Or nuclear power—also known as pink hydrogen. The good news? The expected reduction in commodity costs, technical improvements, and continued vehicle performance will drive this growth.

Hydrogen fuel is a promising solution to help decarbonize transportation. But facility owners need to understand both hydrogen-production methods and the options for infrastructure. If we embrace this innovative technology, we are moving closer to a cleaner and more sustainable transportation industry.